Solar Power 2 Volt Cells

website builders BSH Ltd is an important player in this sector with many innovations. Traction batteries with long life, safe usage, short charging duration, with low electricity costs, provide the best solutions for electric powered vehicles, all with BSH Ltd quality. Traction batteries offer plate capacity ranges from 60Ah up to 155Ah with German DIN norms that are compatible with all types of vehicles. BSH Ltd is always ready to serve after sales needs with on-site services from our widespread nationwide service network.

FIELDS OF APPLICATION

- Forklift Trucks

- Transpallet

- Hand Stackers

- Order Pickers

- Mine Locomotives

- Cleaning Vehicles

SPECIFICATIONS

| Positive Plate | Tubular grid with woven gauntlet |

| Negative Plate | Flat grid with envelope |

| Electrolyte | 1,280 gr/cm3 sulfuric acid |

| Case & Cover | Polypropylene high endurance against heat and beat |

| Connectors | Totally isolated copper cables in DIN norms |

| Cell | In accordance with DIN 60254 standards |

OFFERING INNOVATIVE SOLUTIONS

- Isolated poles with double screw and polypropylene bolt pin

- Flat grid negative plates with envelope to prevent short circuit

- Energy saving up to 20% with Air-Mix system

- Specially produced long life, durable high quality tray

TRACTION BATTERY PARTS

| Product Feature | Product Benefits | |

| Positive Plate | All positive plates are produced with specially designed gauntlet and bottom plastic. | Longer life with minimized active element loss, high protection against short circuits. |

| Negative Plate | All negative plates are covered with a specially designed envelope. | Longer life with minimized active element loss, high protection against short circuits. |

| Seperators | Seperators with high permittivity, minimum internal resistance, mechanically and chemically resistant. | While performing high permittivity, provide high protection against short circuits whilst preventing the contact of positive and negative plates. |

| Pole | All cells are produced with specially designed isolated poles with double screw. | Isolated poles with double screw and polyprolene bolt pin. |

| Plugs (two types) |

Filtered Plugs – Protects the cell from outside substances with the filter system. With special top cover, density and heat controls can be done without opening the cover. Enable hydrogen and oxygen gases to leave the battery safely while charging. | Compatible with Auqa-Matic system. Aqua-Matic system stabilizes the electrolyte density level and reduces the service requirements with less workforce cost. Cell surface will be clear with top-up system. |

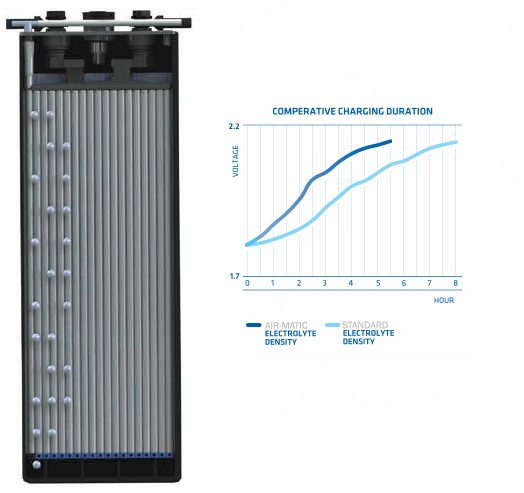

“AIR-MATIC” ELECTROLYTE CIRCULATION CELLS

During the charge or discharge of the battery, the electrolyte (diluted sulfuric acid) is participating in the chemical reaction. This causes different gravity density of the electrolyte from upper part and lower part of the battery. The electrolyte in the bottom of the battery will be heavier. This is a stratification of the electrolyte.

This has a negative effect on the charge and discharge performance of the traction battery. The air circulation system can eliminate this negative effect. During the charge process, as soon as charge voltage approaches a certain value, the pump will be turned on. Air is pumped into each battery from one side. It creates a homogenous gravity density of the electrolyte via air circulation so as to eliminate the stratification directly.

AQUA-MATIC FILLING (TOP UP) SYSTEM

Aqua-Matic filling (top up) system is a unique battery watering system used for batteries in forklifts, golf carts, railway, telecom & power utilities. It replaces manual labour by an automated filling process. It ensures correct water level in batteries, thus avoiding over-filling & spillage or under filling & starvation of batteries. Fast filling enhances productivity levels, reduces stress on manpower and allows direct water supply to battery. Also since there is direct water supply to the cell vent, there is no chance of contamination.

BSH BATTERY AQUA-MATIC FILLING SYSTEM

- Radically reduced filling time = reduction in labour costs and time consumption

- Regular precise maintenance = longer life

- Eliminating the danger of over-filling and acid splash = reduced risk of personal injury

- Minimized water loss = water saving

AIR-MATIC V’s STANDARD SYSTEMS

Fill in this form to make an enquiry

If you would like one of our specialists to contact you for a no obligation discussion about your requirements, please fill in the quick form below.